When it comes to draining outdoor areas or driveways, a trench drain gives a great option to remove excess water from an area. A trench drain provides an elongated platform for water to drain from a particular area; For example, beneath an un-guttered roof edge, driveway, sidewalk, or similar areas where water tends to gather.

What is set into the ground is essentially a gutter, and it works well to help safeguard areas where erosion may be a problem by slowing down flowing water and diverting it to another area.

Trench drains can be created from a broad range of materials, such as cast iron grates, plastic, stainless steel, polymer, etc, including various decorative options to match almost all situations or settings. However, there is a specific trench drain material that is the most suitable for an application, and in this article, you will find out which material it is.

Which Trench Drain Material Is Best for Your Application?

Stainless steel is the best material for trench drain in terms of durability and other factors, compared to some other common options. While other options are also effective, they are not as durable and strong as stainless steel is.

Stainless steel is the highest performer across every drain. Below are reasons the stainless steel trench drains are preferred over other types:

Strength

Stainless steel trench drains being created out of an alloy are more durable and strong, compared with the ones made out of other materials. Since an investment in installing a trench drain system ought to be a long-term one, the decision to choose a stainless steel trench drain is a wise one.

Stainless steel trench drains are also good at withstanding excessive temperatures and resisting scaling, making them just appropriate for application in facilities that see excessive heat or freezing temperatures (which is common in industrial settings).

Additionally, the corrosion-resistant properties of stainless steel allow trench drains that are made out of this material to have the ability to withstand chemical discharges with ease.

Chemical Resilience

Stainless steel is usually chosen because of its typical inertness to caustic chemicals. Stainless maintains its chemical integrity and functionality even under chemical duress, acids, and bases.

Hygiene

Stainless steel is a smooth and solid material, which makes it easy to clean trench drains made out of the material. Furthermore, the non-porous nature of stainless steel does not allow the material to create an environment where bacteria can settle and grow in pores, tiny crevices, or cracks.

That is the reason food processing industries and commercial establishments such as restaurants, hospitals, farms, and food service facilities prefer to get stainless steel drains installed on their premises over drains with other materials.

Allows High Flow

Stainless Steel trench drains allow a high flow of liquid, making them eminently appropriate for commercial and industrial applications. With the widths of trench drains varying from three-fourths of one inch to more than forty-eight inches, stainless steel drains can accommodate all volumes of flow.

Safety

Due to the strength, there is a low probability of a trench drain made with stainless steel crumbling under any kind of weight and pressure. This lowers the chances of anyone suffering from an injury on account of a broken or damaged trench drain system.

Moreover, stainless steel grates are lightweight and can easily be removed to facilitate the cleaning of the drains, reducing the likelihood of workers getting hurt accidentally while carrying out their job.

Economy

In the long run, the installation of a stainless steel trench drain saves money in various ways. However, stainless steel is not just an intrinsically economical material, its longevity and durability also make it more so.

Stainless steel grates, in particular, will not require replacement in a very long while, as a result of their strength and durability, thereby saving thousands of dollars in the expenditure of replacement. Also, the fact that stainless steel trench drains can easily be cleaned helps to save money.

Low Oxidation Potential

Where cast iron may corrode or oxidize and where polymer may degrade, stainless steel holds up over time. That is to say, stainless steel exhibits greater functional strengths relative to its counterparts.

Efficient and Minimal Upkeep Needed

Trench drains made with stainless steel are lightweight, and easy to install, and a single person is okay to manage them. That is the reason stainless steel trench drains have become the automatic choice for several industries.

Beauty

Stainless steel is shiny, and sleek, and adds to the contemporary appearance of any facility it is applied in. It does not rust, and it helps to create an atmosphere of pride in the entire look of the physical part in which it is installed.

Versatility

There are several options available in the application of stainless steel trench drains. For instance, one could order stainless trench drains as long as forty feet, to minimize the need for welding.

The premier manufacturers of stainless steel can create various custom-designed drainage systems, based on the needs of a multitude of industries such as meat processing, food and beverages, and chemical industries.

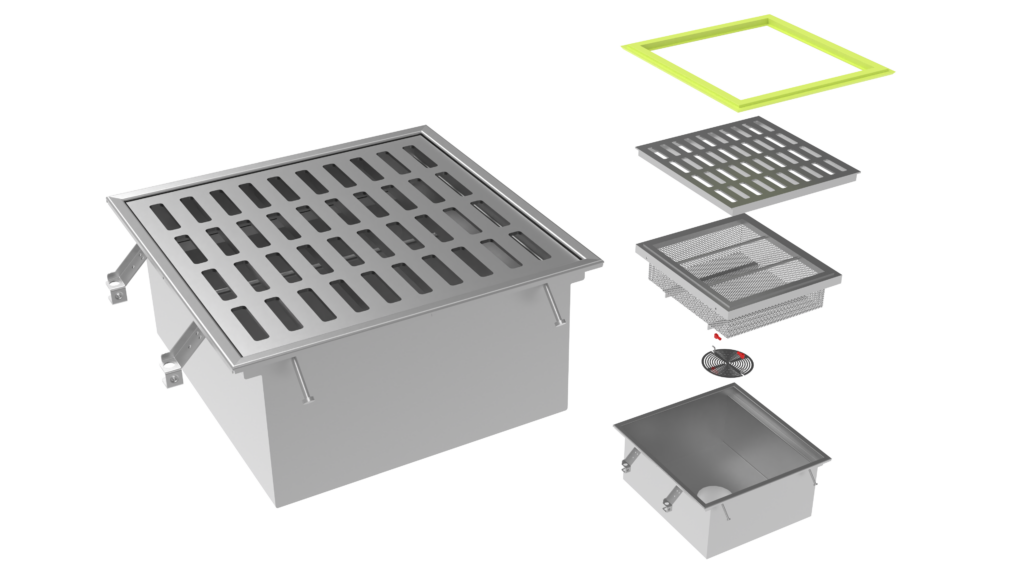

Additionally, stainless steel trench drains are accompanied by various styles, including a V-bottom profile, slot drains, and those equipped with floor sinks or catch basins.

Applications and Uses of Trench Drains

Trench drains can be applied in almost all industries of today, including private home use. Below are some of those industries:

Heavy Duty Industries

Trench drains can be seen in military facilities, warehouses, airports and transportation terminals, docks and ports, manufacturing facilities, as well as refineries. That slot drain is capable of holding a great deal of weight makes it the best option for these industries, because planes and military equipment tend to weigh a lot.

Automotive Industry

The automotive industry, including dealerships, gas stations, parking garages, and car washes, can as well benefit from the installation of a trench drain to help gather and clean up the waste that must have been created by cleaning. Just like the previous industry, those in the automotive industry gain from the slot drain system because of its ability to hold heavy loads, and its ability to be resistant to corrosion.

Landscaping

A trench drain can also be used for landscaping purposes in landmarks, fountains, and parks, since it will make an effective method available to get rid of groundwater that would or else gather and potentially cause flooding and/or property damage.

Food and Beverage Industries

When it comes to industries like these, a trench drain is unbelievably important because they make sure that these facilities are amazingly clean and bacteria-free. This includes breweries and wineries, slaughterhouses, seafood markets, abattoirs, and dairy farms.

A trench drain system is additionally resistant to corrosive materials that may be used to help in cleaning and disinfecting those areas.

Education, Residential, and Commercial Locations

These groups of places are as well where a trench drain can generally be found. Bathrooms, commercial kitchens, gyms, playgrounds, and swimming pools are just some of the particular areas where it is beneficial to have a trench drain.

Animal Facilities

Facilities of animals like farms and zoos generate a lot of ground waste. They also make use of strong solutions to help in cleaning and disinfecting their facilities at the end of the day. The easiest way to clean is by rinsing off so that it travels down a trench drain.

Steps to the Installation of Trench Drains for Application

The key steps in the installation process of trench drains are highlighted below:

Plan and Excavate

The first step in the installation of a trench drain is assessment of the planned location for the trench drain. It is important to review the slab thickness and expected load for every location. Thereafter, the trench drain system is structured to prevent buildup. Sanitary and safety standards are critical to be met as well.

Trenches will then be excavated to give room for at least 4 inches of concrete and expansion joints around the channels. If the planned slab happens to be thicker than 4 inches, the surrounding concrete depth will have to match the slab thickness.

Channel Lay Out

After the excavation of trenches, the channels will then be laid out working backward from the deepest point and ensuring that the flow arrows point toward the outlet. After that, outlet ends will be opened and attached to the deep end of the channel. Then an end cap will be fixed to the shallow end.

Channel Assembly

Sections of channels for the trench drain system will be connected using silicone sealants. Construction covers will then be positioned such that they will overlap joints, avoiding misalignment.

Rebar Installation

Rebar will be installed into the anchor clips that are situated on the sides of the channels, and afterward driven into the ground. Each section of the channel will then be confirmed that it is adjusted to the proper elevation, typically between 1/16 to ⅛ inch below the completed slab.

Concrete Pour

With all the channels in their final positions, anchored with rebar and protected with wire or screws, installation of concrete pads will then take place. Pads set about the rebar, both on and under the sides of the channel, will have a minimum of 4-inch thickness and will be recessed to the accurate depth below the slab. Vibration is then applied to inhibit any void during the pour.

Expansion joints are placed on all sides of the channel, and coupling is employed to connect drain pipes to the channel outlet.

Inspection

Construction covers are removed after a minimum of 24-hour concrete time set. The channels and piping will then be inspected, clearing any debris as well. Thereafter, the grating will be installed and safeguarded with screws.

Slot Drains

Stainless steel can be used to make what is known as a slot drain. Slot drain creates an amazingly durable product that is conformant with the laws and regulations of drainage, it completely removes the trouble of foul odors, is resistant to corrosion, can withstand heavy loads, is more hygienic, and it is typically more pleasing aesthetically.

Slot Drain is a one-piece, built-in sloped and surface drain system/open floor drain that has a linear slot on top. The linear slot removes the need for grating, making it the most sanitary, durable, and cost-effective drainage system available. It is applicable wherever ground or floor surfaces have regular cleaning requirements or are subject to fluids.

In addition, a slot drain naturally solves many of the issues that arise in a trench drain system. Contrary to the classic grated trench drain, slot drains do not require heavy grates. These grates ought to keep larger items from falling off into the drainage channel and to come up with a more even surface for people and machinery to walk over.

However, these grates are unbelievably heavy and can result in worker injuries when the time comes to lift them (the grates) for cleaning. They can as well break from bearing excessive weight and will consequently erode over time as a result of exposure to chemicals.

Since the slot drain does not need grates, those concerns are completely removed. Moreover, a slot drain system is much easier to clean and sanitize, capable of withstanding very heavy loads, yet highly durable.

Beyond that, the fact that slot drain systems are made of corrosion-resistant stainless steel makes it possible to withstand excessive temperatures, and are conformant with the standards put in place by the American Disabilities Act. All of these points make a slot drain an excellent option for everywhere drainage systems are called for.

Choose Quality Trench Drain Materials for Application

Stainless steel can be recycled. Much of it is made from recycled materials. Hence, it is a friendly product environmentally.

Considering the various reasons stainless steel is the best material to use for your trench drain installation, as well as the advantages of slot drain, ensure that you choose to build a quality stainless steel trench drain system.

Remember, trench drain systems are a long-term investment. And if you get it right at the beginning, it will be beneficial to you.