Having the right drainage for any facility matters. There are so many reasons that your drainage needs to work properly in any environment, but in a business location, drainage is an even more critical part of the safe operation of your company. The proper drainage can have a big impact on your business practices and the chances that you might have to shut down to deal with a contamination issue.

Buy drains for pharmaceutical companies if you are looking to upgrade or install drainage for this kind of company. There are specific types of drainage that are ideal for this kind of work environment. Having the right drainage in place for your company location is key for safety and so much more.

The Reasons That You Need to Have the Right Drainage At Your Pharmaceutical Company

There are many reasons that the proper drainage has to be installed in an industrial location of any type. When you make products or food of any kind, there are regulations that guide what kinds of drainage you need to have in place. These rules exist for good reasons, not least of which are safety and safe practices when making consumer products.

1. Safety

The safety of your business is something that you cannot compromise on, and drainage has a lot to say about how safe your business operations are on a daily basis. Drainage impacts the conditions of workspaces at your business by preventing standing water that can cause accidents. It also helps to make sure that chemicals that are used to clean and sanitize workspaces are removed entirely before products are made.

Some chemicals and byproducts of food or medication production are actually toxic. These will need to be washed and drained off the surfaces of your workspace to make sure that your staff are not exposed to unnecessary risks as they work. Safety also has something to do with whether or not there is standing water in areas that should drain properly, as mold and bacteria can also expose your staff to health risks.

2. Contamination-Free Products

Products that you sell to the public have to be kept free of contaminants for obvious reasons. The health risks associated with incorrectly made products are significant, and medications need to work correctly to protect public safety. Products that have been contaminated by mold, bacteria, or even moisture that should not have been present at the time of their creation should not be sold.

When you create products like medications, you need to ensure that your workspaces are free of any moisture and drainage that could cause the products you are making to be altered in some way. There are lots of chemicals that are used to create medications, which means that preparation of the work area and keeping it clean and dry is almost always required.

3. Regulations

Most production businesses that make food or other items like medications have lots of stringent requirements that they must follow to ensure that work areas are clean, safe, and free from chemicals and fluids. These regulations are for the safety of the staff who make the products, as well as to ensure that the products that are made are safe to be consumed.

Regulations have to be followed by law, and you cannot afford to run afoul of the requirements for your industry niche. Following regulations means having drainage in place that supports the safe production of your products and ensures that the drugs that you are creating will be safe for the public to consume.

4. Fighting Contaminants

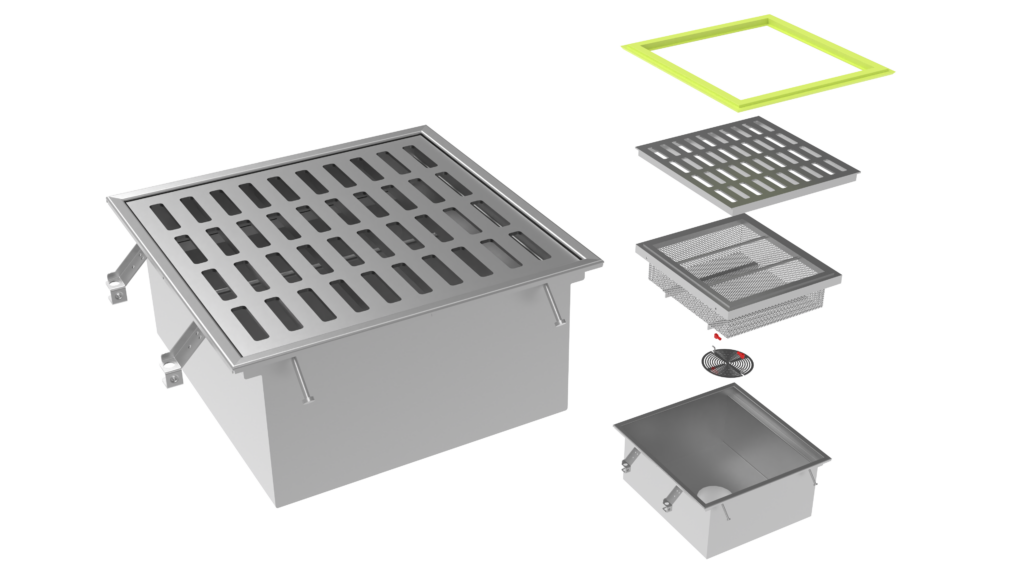

The right drainage can actually prevent the growth of mold and bacteria, which can find places to live in and around your drains in some cases. You need to clean out your drainage on a regular basis as well, but drains that are made with sanitary manufacturing in mind can make it much less likely that you will run into these issues.

Drains that are made to support sanitary operations will have increased flow capacity and be made for quick and easy access for cleaning. These drains will also have enhanced durability and resist harsh chemicals, which can break down other forms of drainage. Many of these drains also have improved flushing systems to help keep things clean and production-ready at all times.

Drains that are made with this kind of production environment in mind are ideal for companies that are looking to fight contaminants the easy way. Working smarter and not harder is important when you need to make sure that your staff can work properly and efficiently each day at your facility.

Having the Right Drainage in Your Pharmaceutical Production Facility Matters

There are a host of reasons for having the right drains in your pharmaceutical production facility. You probably have regulations to follow, and you likely also want to be sure that you can offer a safe workspace for your staff each and every day. Your drainage needs to be easy to access and clean to prevent mold and bacterial overgrowth. These factors are easily managed when you have the right drainage in place at your facility, which is why upgrades can be important for any business that creates pharmaceutical items.

When you make products that the public consumes, there are also regulations that dictate how you set up your workspaces and the requirements for sanitation and safe production conditions. You need to keep all of these variables in mind when you are setting up the drainage at your business. Working with the right drainage company can have a big impact on the way you set up your drainage system, as well as the products that you use to do so.

Consider drains that are made to stay sterile without much intervention when building a drainage system for your pharmaceutical production spaces. This makes a big impact on the ease with which you can keep your work areas safe and production-ready, and it also saves time and helps you to avoid costly shutdowns.