Having the right food and beverage production facility drainage matters for so many reasons. You need to make sure that you are aware of the reasons that upgrading or installing the right drainage is so critical in food and beverage production. You might be aware of the fact that these drainage solutions can help avoid shutdowns and contamination, but there are so many other reasons that you might want to take a closer look at your existing drainage systems.

Food and beverage drainage needs to operate in specific ways and be made of specific materials to work at optimal levels for your business. It’s critical to have the right drainage in place to make your business operate properly, safely, and smoothly. Drainage is just as important as the other aspects of your workflows and assembly lines, and you cannot afford to forget about this key part of your business workflows and systems.

Why You Need the Right Drainage For Your Food and Beverage Production Facility

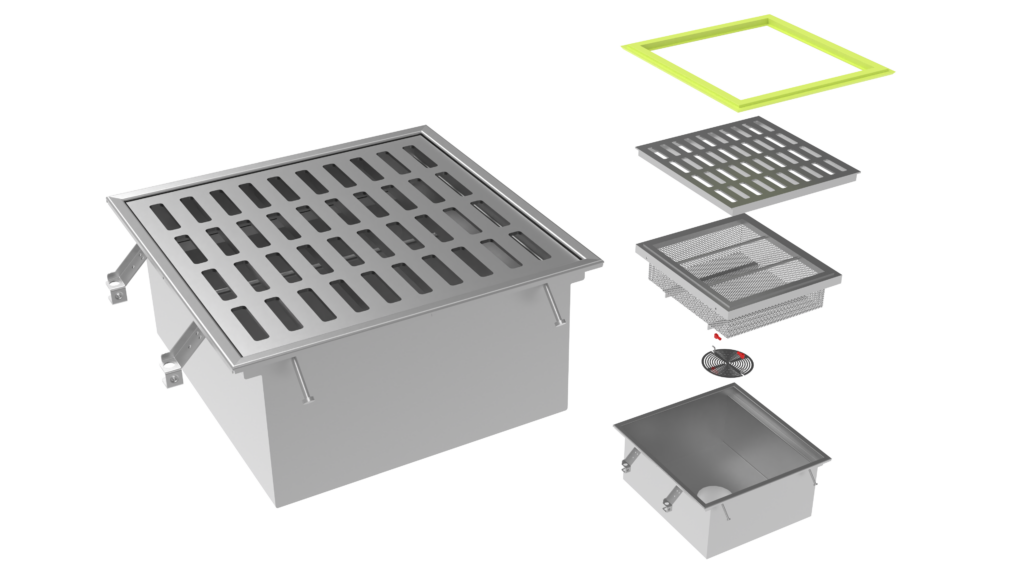

The right drainage for your food and beverage facility is important for safe operations as well as safe food production. The kind of food or beverage that you create can have an impact on the drainage components that you have to include in your drainage setup. You might need catch basins or other solutions to help drain floors fully and to handle runoff, which cannot be allowed to enter standard storm drains.

1. Safety

Water on the floor is water that could cause an accident. There are lots of processes when making food and beverages that use water, and even cleaning and sanitizing can use a lot of water. You need to make sure that this water can be removed from the work areas at your business for a variety of reasons, but safety is at the top of the list.

Your staff cannot work safely if there is a chance that they could slip and fall in the water that should have been captured by your drainage solutions. Water is a hazard that can make floors slippery, and this can lead to accidents that could have been avoided.

If you operate a facility like a brewery or another beverage-making business, you will need to remove standing water because it might have chemicals in it that could be harmful to your staff if they are exposed for long periods of time. Standing water can create health risks and hazards of all kinds, which is why it needs to be dealt with correctly throughout the day.

2. Preventing Contamination

Contamination is a major concern when it comes to beverage and food production for many reasons. Standing water, or water that is not flowing out of drainage solutions at the right rate, can lead to bacterial overgrowth or mold formation. These threats can contaminate food and drink with ease, leading to a health risk for the public and contaminated work areas that might cause health risks for your staff.

Keeping the work areas at your business free from standing water ensures that you are not creating products that are unsafe to consume. Having the right drainage in place also ensures that you are not exposing your employees to risks that should be avoided. The water that is used for cleaning and production, and the liquid runoff from work processes, can all lead to health risks as well as traditional safety risks. You will want to keep both of these concerns in mind when you are planning a drainage system for your facility.

The drainage that you add to your work areas needs to resist growing mold and bacteria, and it needs to be designed to drain fully and correctly at all times. There are specific design features that the drainage in your facility has to include to meet regulations as well. You need to be sure that you are considering these factors as you install the drainage at your business location.

3. Regulations and Laws

Food and beverage production facilities need to abide by a list of laws, most of which are federal in nature. These laws are in place to protect the public from being sold contaminated food and drink, and they have to be followed each day, all day long, while you create products.

Your facility might need to have specific kinds of catch basins, drainage types, and drain covers in place to meet guidelines. You will likely also need to follow specific sanitation processes and use specific products as you clean up between production runs.

These laws and regulations are intended to keep contaminants out of your facility, but they can be hard on drainage that is not made for the task of holding up to this kind of daily strain. Drainage that is made specifically for your kind of business is important to invest in because cleaning products and the kinds of liquid runoff that are generated by work processes can break down standard drainage products.

The Right Drainage For Your Production Facility is Key

When you have the right drainage in place at your facility, you ensure that you are able to keep your staff safe all day and that you are creating products that are safe to consume. Food and beverage creation plants and facilities have to abide by a list of requirements and regulations that ensure that the products they create are safe to be consumed by the public.

You will need to make sure that the drainage that you have installed at your facility meets these standards, both for your staff and to maintain the quality of the products that you are making. Drainage is just as important as the other aspects of your food production processes, and you cannot afford to take this part of your business lightly. Working with a skilled drainage product supplier can help you create drainage systems that will hold up for years and work perfectly for your needs.