Operating a food and beverage production location means being familiar with a whole range of requirements. Some of the rules that you have to follow are federal, and some are local or at the county level. These rules are intended to ensure that food and drink production is conducted safely and that products that are sold to the public are safe to consume.

Drains for food and beverage facilities are one of the items that are required to be correctly placed and designed in order to meet the stated guidelines for this kind of facility. You will need to be aware of the various other rules and regulations that impact your business’ production and workflows, but we will discuss drainage requirements and needs in this guide.

What Are the Requirements for Correct Drainage in Food Production Facilities?

There are many requirements that must be met for a food or drink production location to remain open for business. These requirements have to be met in order to prevent contamination in the products that are made and sold to the public, and they are also in place to ensure safety for the people who work at the facility.

Businesses that are not compliant with these requirements can face significant fines and might even be shut down for a time if they are not found to be compliant with regulations. Beyond these kinds of regulatory issues, it is never ideal to have staff get hurt while they are working, and businesses of all kinds should want to avoid harm in the workplace.

These are the requirements for correct food or beverage facility drainage:

1. Ease of Cleaning

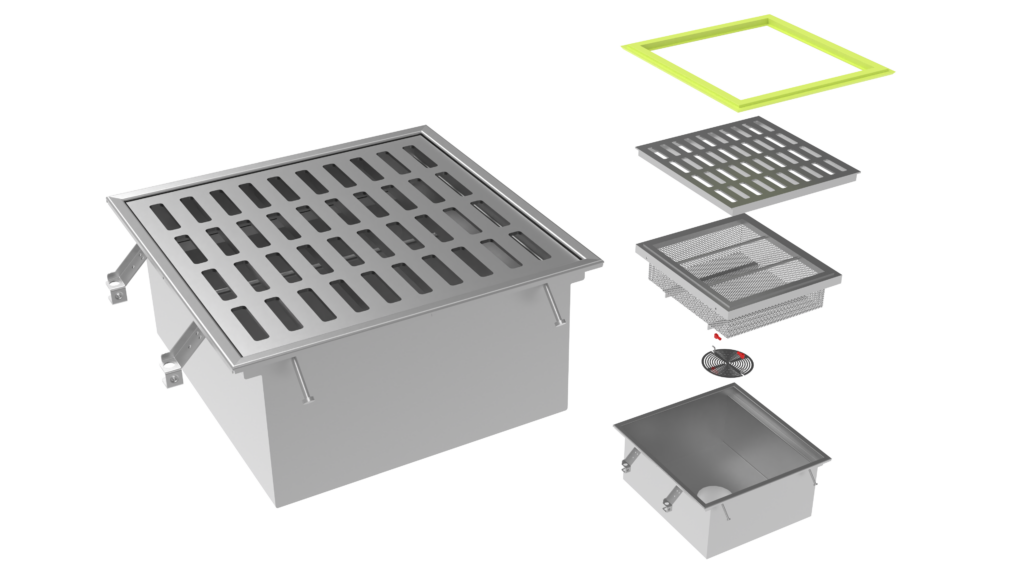

One of the main things that your drainage solutions in your business need to provide is an easy cleaning process. Older style drainage can be tough to access and can be hard to keep clean. This can lead to problems with standing water or areas within the drain where cleaning is not possible. These places that are never cleaned or sanitized can harbor contaminants that can impact the health of your staff and the quality and safety of the items that you are producing each day.

You need to be able to count on your drainage solutions to be simple to access and easy to clean. Drain covers should lift off readily, and small entry points should be maintained to prevent issues with standing water. Drain material can impact the cleaning process as well, and stainless steel is often the preferred material for drainage in this kind of business location because it is hard for bacteria to stick to smooth surfaces. You need to be sure that any drainage in your facility that is not simple to clean is replaced in favor of a much more ideal and compliant solution.

2. Meets Code and Regulatory Requirements

Federal guidelines actually provide you with a blueprint for the correct drainage solutions for your business. Sanitary drains are made from materials that can withstand hot water and chemical interactions. They are made to prevent slips and falls, and they are easy to clean and care for. Access should not be difficult when cleaning, and catch basins and other collection point solutions should be in place to ensure that caustic or unsafe water and solutions are kept from being disposed of improperly.

The codes and regulations that are enforced for businesses in the food production niche are created to ensure that the food and beverages that you are making are safe and to prevent accidents at your workplace. It should be your first concern to follow these guidelines when you are creating drainage solutions or operational workflows.

3. Easy to Maintain and Clean

No drainage in your facility should be hard to maintain or care for. Not only will maintenance issues slow down your production efforts, maintenance problems can lead to issues with contamination that could have been avoided. You need to be sure that your maintenance solutions are simple, reliable, and easy to complete during workflow processes.

Catch basins and other drainage collection points need to be accessible for cleaning, and you need to ensure that staff have the right tools to clean these areas within the facility. There are many drainage-specific cleaning tools that you can provide to your staff to help them keep your business sparkling and ready for the next production effort to be completed. Easy maintenance is a must, and if you have drainage that is hard to care for, it should be replaced.

4. Correct Materials and Design

The right materials for your drainage solutions can have a significant impact on the safety of your operations. You need to be familiar with the requirements for safety that are called out in federal guidelines, as they are paired with the kind of production facility that you operate. Caustic runoff or chemicals are not ideal for drainage that is not made to withstand this kind of exposure. Breweries in particular require specific kinds of drains that can handle high heat as well as caustic materials exposure.

Being aware of the ideal materials for your drainage solutions can make a big difference in the safe operation of your business. Be sure that you are aware of the kinds of drainage materials that are made to handle the demands of your business operations before you start installing drains that will not hold up to daily work processes. You also need to consider the design of your drainage so that you can create workspaces that are safe and easy to navigate.

Food and Beverage Facilities Need Correct Drainage for Many Reasons

There are so many reasons that you need to have the right kinds of drainage installed at your production facility. You need to comply with regulations but also keep your staff safe each day. Creating quality products is almost impossible if your facility is not set up correctly. Use this guide to ensure that you are going to be able to avoid fines and shutdowns while crafting quality products that are safe to be sold to the public.