Trench drains are an essential part of any chemical plant. They carry away water contaminated with chemicals and other materials you don’t want to be around. Trench drains also prevent moisture from building up, keeping the area safe.

Overall, there are plenty of reasons why you need to have trench drains at your chemical plants. If you want to learn more, keep reading— everything vital that you need to know is below!

Why Are There Trench Drains in Chemical Plants?

Trench drains are in chemical plants for several reasons, namely, to collect water or chemicals and transport it away safely. If there’s a chemical spill, the drains direct the substances out, protecting employees in the plant and making the cleanup process a lot easier.

The drains also remove excess water during cleaning and can help prevent falls from happening on the property. Lastly, it’s worth mentioning that trench drains can also contain utility lines, which there are usually many of in factories, no matter the chemicals there.

Overall, there are so many reasons why trench drains are considered requirements at chemical plants, making them essential to have in place.

The Importance of Trench Drains at Chemical Plants

DuraTrench has experience creating drain solutions for various plants and other buildings. We understand how vital these systems are to keep a chemical plant functioning smoothly. If you don’t have one in place, you’ll want to reach out to our experts on the DuraTrench website to have us set up one for you.

Chemical plants must be kept as sanitary as possible and follow strict guidelines. These trench drains ensure that everyone at the plant is safe too.

These are all of the reasons why having trench drains at chemicals plants is so important:

Trench Drains Protect Workers From Chemical Spills

The most crucial reason for trench drains at chemical plants is that they prevent severe damage from leaks and spills. The drainage system catches chemical run-off and transports it somewhere it can be disposed of properly.

Without a drainage system in place, cleaning up chemical spills is difficult and dangerous since you’d have to do more of the work while at-risk of touching the chemicals. Depending on what your plant does, the chemicals could be harmful to make contact with.

A plant must ensure its workers have a safe environment, making reliable drainage trenches necessary.

Trench Drains Prevent Slips and Falls

Additionally, having quality trench drains can prevent workplace slips and falls. It’s not uncommon for chemical plant floors to get wet for various reasons. Drainage trenches can prevent parking lot run-off from overflowing and causing water damage and slipping.

Falls are always a workplace hazard but can be significantly reduced by implementing safety measures. In fact, many guidelines require that plants have drainage trenches, so you’ll want to ensure that your plant follows these rules.

Trench Drains Stop Water Building Up During Cleaning

Next, chemical plants also have a lot of machinery that requires frequent cleaning with water. The spray can easily run off the equipment, which builds up in the middle of the room.

If the plant cleans its equipment this way, you’ll want to ensure that you have proper drainage. The water from cleaning should travel into the trench drains, where it’s taken away and disposed of properly.

In short, trench drains are necessary to prevent water from gathering under equipment and in the center of the room during cleaning, where it could cause many different issues.

Trench Drains Act as Utility Transports

Trench drains can work as utility transports. These drains allow utility lines and more to run underground, where they’re out of the way to reduce hazards. Since chemical plants often have several utility lines, having trench drains in place makes it possible to keep them organized and safely out of sight.

These lines also come with several conditions and guidelines that chemical plants need to meet. If you’re unsure what to do, DuraTrench can help set you up with a quality system.

Trench Drains are Easy To Clean

Trench drains are also easy to clean with the right equipment, so you won’t have to worry if there is a leak or spill. All of the methods you can use don’t require anyone to make contact with the chemicals. Regular maintenance is also simple and keeps the system clean and free of clogs.

The most popular methods include hydro-blasting and the use of specialized cleaners. What you do will depend on the chemicals that travel through the drains, but our trench designs ensure cleaning remains straightforward.

Plus, if a spill occurs, they’re much easier to clean than the ground. When chemicals get on the floor of a plant, there are very specific steps you need to take to safely clean the area while ensuring no trace of the chemical remains. Having a drainage system makes the cleaning process much easier.

Installing Trench Drains in Your Chemical Plant May Be Required By Law

Depending on your chemical plant’s materials, there may also be some legal requirements. You may need to have some kind of drainage system in place to ensure the safety of the staff present in the event of spillage or an emergency.

A trench drain can help keep the chemical plant up to code. You must understand the rules and guidelines in your area to know legally what the chemical plant is responsible for.

Custom Trench Drains Fit Every Facility

Lastly, you have many options for customizing your trench drains to fit your chemical plant when you choose DuraTrench. This feature is important because we can tailor-fit the drains throughout the plant.

You may even need to have certain sizes in different areas, which is why customization is necessary for chemical plants. Many chemical plants also handle different materials at once, so you can choose different trenches to match.

Overall, chemical plants need trench drains customized to their unique circumstances as well.

What Happens to Chemical Plants Without Trench Drains?

If the trench drain failed (or wasn’t there, to begin with), several issues arise immediately. Water can gather for many reasons, leading to employees falling. Plus, water in chemical plants can contain hazardous materials, depending on where it came from, which would also put employees at risk of making contact with contamination.

Chemical plants need to abide by certain rules as well. That means having a proper drainage system setup. Without one, the plant may not pass any inspections.

To summarize, chemical plants can’t operate without a high-quality trench drainage system. The drains work to keep employees safe and are often a requirement to stay open and functional, depending on the location of the plant.

Why Chemical Plants Need Professional Trench Drains

A lot of behind-the-scenes effort goes into installing trench drains, especially in chemical plants and other similar settings.

You need to ensure they’re in the proper area, have the correct slope, and are made of materials that resist damage from powerful chemicals. If you don’t have experience doing that, the trench drains could fail when you need them.

That’s why you must have a professional team perform the installation for you. Experts know the correct slopes to use, making the installation efficient and reliable.

Our experts at DuraTrench know how to prepare durable, long-lasting drainage systems that you can rely on for years.

Where Are the Trench Drains in Chemical Plants?

Every chemical plant is slightly different, so you’ll find trench drains in various areas around the facility. However, you’re most likely to see them anywhere there are chemicals nearby, so they can be in the best place to manage leaks and spills.

Trench drains are below the floor’s surface, keeping them out of the way. The floor remains flat and safe to walk on, but the drains are just underneath to deal with moving chemicals away from where anyone would make contact with them.

Overall, you’ll find trench drains almost anywhere in a chemical plant where there’s water or other liquids. You never want to have standing water in these buildings, so it’s crucial to have plenty of drains throughout the plant.

How Are Chemical Plant Drains Different?

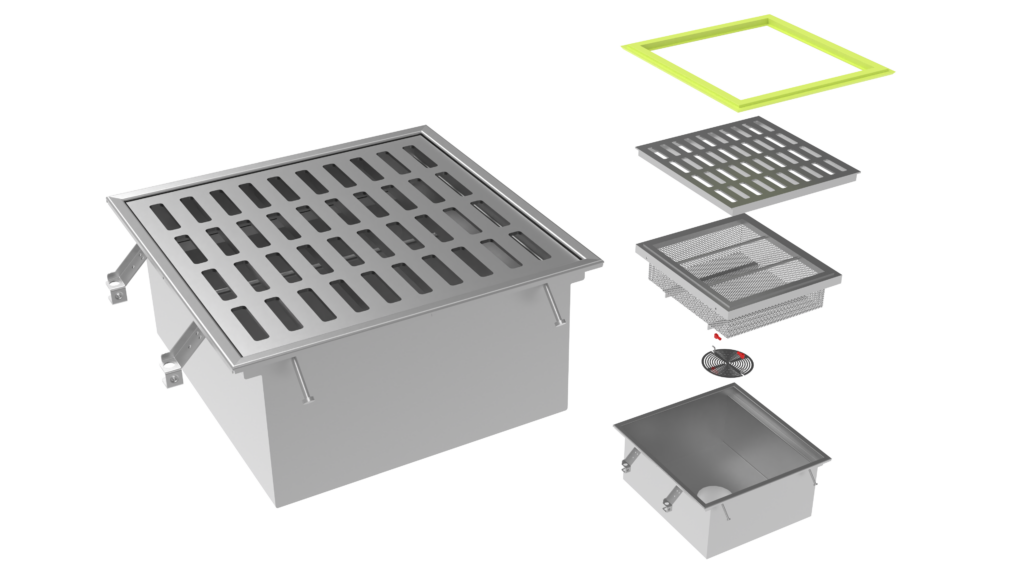

Chemical plant drains are very different from those you see alongside the road. They’re made of materials that resist corrosion and can offer double containment. They can come in various sizes, although what you choose is specific to the chemical plant. They also come in very large sections, so there are fewer seals where contaminated water could escape.

Most trench drains come with visible grating over the top. However, chemical trench drains are a bit different. These have a plywood top, which protects the drain underneath, and ensures no one accidentally touches chemicals traveling through them. The wood also allows you to attach braces to them.

You can’t install standard trench drains in a chemical plant and expect them to last. They’ll fail quickly since they can’t handle harsh chemicals nearly as well. Choosing trenches consisting of materials that won’t break down immediately is essential. If you need help deciding what’s best for a chemical plant, you should contact us or check the chemical resistance guide to learn more.

Overall, chemical plant drains differ from rain trenches since they perform more demanding tasks and need to be much more durable.

What Are Double Containment Drains For?

Double containment drains are best for chemical plants due to their insulating abilities. Chemicals can run extremely hot or cold, causing condensation to appear on the outside of regular trench drains.

You don’t want that to happen, as it can cause severe damage to the areas around the drain. However, with a double containment wall inside the drainage system, condensation can’t form. It’s another layer of protection for transporting liquids that have extreme temperatures.

It also provides a second layer for contaminated liquids to flow into should the first layer fail. Having extra protection is necessary for plants that handle hazardous materials.

In short, some chemicals will require a double trench drainage system, but not all of them.

The Benefits of Trench Drains in Chemical Plants

There are several benefits to installing trench drains in a chemical plant. They increase safety and cleanliness, don’t take as much time or effort to install as other systems, and are more cost-efficient.

Let’s break these benefits down in more detail.

Trench Drains Improve Chemical Plant Safety and Cleanliness

First, trench drains offer the benefit of safety and cleanliness to chemical plants. They keep the floors dry, which prevents employees from slipping. Plus, they make keeping the equipment and floors clean more manageable, allowing the plant to operate safely.

Safety and cleanliness offer extreme benefits to any plant, no material the materials it handles.

Trench Drains Are Easy To Install in Chemical Plants

Compared to other types of drainage solutions, trench drains are extremely easy to install in chemical plants. It only takes an expert a few days to install them, instead of several weeks like it would for other, more complex systems.

Our custom trench drain systems come with easy-to-understand labeling and guides, allowing our team to assemble them quickly and efficiently. You can expect the process to go smoothly with all these features.

Trench Drains are Cost-Efficient for your chemical plant

Finally, trench drains are much more cost-efficient than other drainage systems, especially the ones that can safely transport chemicals. Even though they cost less, you can still trust that they’re very high-quality, making them an outstanding option for any chemical plant.

Install Trench Drains in your Chemical Plant Today

If your chemical plant requires custom trench drains, don’t wait to install them. They’re the best option for most plants, and having DuraTrench provide your drainage system offers you many benefits, including boosting the safety and cleanliness of the plant.

Many areas also require you have a system in place in case of leaks or spills. The trench system also makes it much easier to clean the equipment in the building with water, so you should never go without them. Overall, it’s important to offer those in your workplace a safe, clean space, which means they should never have to handle chemicals. Let a reliable drainage system do it instead.