Creating food and beverage products that are safe to be enjoyed by the public is important work. It also requires that a high level of care is provided throughout the creation process, no matter what kind of food or drink your company makes. You need to be sure that you are following the regulations that are put in place by the government so that your food products can be crafted properly and sold.

Food and beverage drain solutions are a critical aspect of sanitizing work areas and keeping facilities open to operate full-time. Your staff need to be able to clean properly and ensure that sanitation is maintained. If you are not sure about the other regulations that need to be followed for your food and beverage production facility, this guide will be a big help.

Regulations for Food and Beverage Facilities in Production Areas

1. Drainage

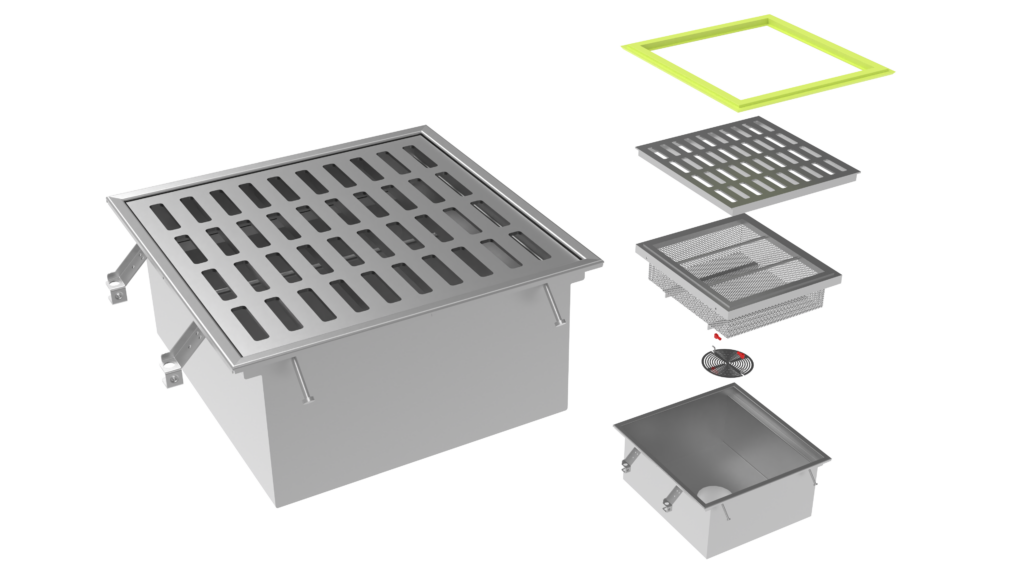

Food and beverage creation areas must be drained properly to prevent issues with contamination, combustion, or chemical exposure. These areas need to be sloped properly to allow floors to drain after cleaning, and they need to be created to facilitate cleaning and sanitizing of work areas throughout daily operations. You will need to have the right kinds of drains in place in your working areas so that you can be sure that you are not going to have to close down your plant for issues with sanitation on a regular basis.

Sanitation needs to be maintained with proper chemicals, but these products also need to be washed away after cleaning processes are done so that food and beverage products are not contaminated with these products either. You will want to make sure that you are looking into slot drains, which prevent trip hazards and allow water to be easily drained away from floor surfaces. Catch basins and central floor drains can also help to capture moisture and direct it to the right areas where drainage can be efficiently taken care of.

2. Record-Keeping

This is one of the most essential aspects of any production business when it comes to making food and drink products. Be sure that you are keeping track of each lot of product that you make and that you have stored chemicals, ingredients, and sanitation products properly and in the right numbers. These kinds of records ensure that costly mistakes are not made which could lead to issues with products or even public health risks.

Businesses will be guided by industry-specific regulations about how to keep records to track work processes, safety issues or problems, and production lots. You will need to follow these regulations to be allowed to continue to keep your doors open each month.

3. Registration

Your facility will need to be registered with the proper entities before you will be allowed to be open for business. You will need to be sure that you find out which local entities you need to be registered with, and you will, of course, need to register with the federal groups that provide regulation, audits, and other essential services for your specific niche area.

Companies of this kind will almost certainly need to be registered with the FDA and OSHA. You will also need to be sure that you are following requirements like the CGMPs (current good manufacturing practices) during daily operations.

Registration with these groups and entities ensures that your company is compliant and that you get information about regulatory changes and other critical notifications throughout the year. There are lots of reasons that you need to be registered with the right entities, and you cannot skip this step under any circumstances.

4. Ongoing Compliance Updates

All food production businesses will need to ensure they comply with ongoing regulations and regulatory changes. You will need to be sure that you are sharing these changes with staff as well. Best practices can change, along with sanitation requirements, and you need to be sure that you are continuing to train and improve in these areas at all times.

This is one of the most important parts of operating a safe and compliant food and beverage production location. Even things like cleaning and storage regulations can change, and your facility absolutely must comply with these changes to be operating in a legal manner.

Weekly meetings at a minimum are common at businesses in this niche to be sure that these regulations are correctly observed and work processes are properly updated over time. You might need a specific team of employees who handle these kinds of updates and the training and notification that accompany them.

5. Environmental Regulations

All businesses that create products of any kind are subject to oversight and monitoring by the EPA and other government organizations that are concerned with protecting nature and the public from chemical exposure or possible harm. These considerations are often quite critical to things like the design of the drainage on your site, and they also govern things like the disposal of products, ingredients, and wastes.

Environmental considerations are part of safe operations for all businesses, and your food or beverage creation plant is no different. These requirements can also shift over time, requiring that your business practices and workflows change along with them.

Maintaining Safety and Compliance Are Critical Aspects of Food and Beverage Creation Processes

When you operate a food or beverage creation plant, you need to be sure that safety, environmental considerations, and proper sanitation processes are observed at all times. These considerations require that the creation floors are kept sanitary, that storage is done the right way, and that staff are handling food and ingredients safely throughout the day.

You will need to handle all of these processes to be able to operate safely, and your company is not exempt from compliance with these concerns and considerations. The more you know about compliance processes and sanitation requirements, the less likely it is that you will have to worry about business shutdowns or compliance issues.