DuraTrench creates drain solutions for all kinds of processing locations. From breweries to food processing locales, we can create the right drainage systems for your business needs. Any kind of location where food is handled and prepared requires the right kind of drainage for safety and sanitary requirements and we are experts at these kinds of installations.

These locations can be challenging to create drainage solutions for due to the kinds of traffic that the preparation areas can experience. Due to foot traffic and heavy equipment traversing the floors, food processing plants often require the sturdiest drainage systems that we make. Another additional concern in these kinds of processing locations is making sure that harmful bacteria cannot grow and proliferate through the drainage system.

Creating the right drainage system for a food processing plant is a complicated process and requires skilled guidance to make sure that it is done properly. If you are ready to learn more about the ins and outs of creating a drainage solution for your food processing plant, read on!

Trench Drains for Food Processing Plants

Processing facilities are held to a very high standard related to sanitation as well as safety. You will need to think about all of the many factors that contribute to your processing plant passing inspections when you design your drainage system. The trench drain systems that you select for your food processing plant is important for many reasons, from sanitation to safety, to the production of products that are safe for human consumption.

Trench drains are used to carry away contaminated water and other substances from food preparation and processing locations and your drainage system needs to ensure that the floor remains dry enough for safe daily operations. Preventing slips and falls is just as essential as making sure that you can maintain proper sanitation standards during your daily operations.

There are various kinds of trench drains that you can use in a food processing plant’s drainage system. You will probably use a combination of a variety of trench drain styles and trench drain accessories when you are designing your food processing plant’s drainage solutions. Some trench drain styles are not suited for every kind of use, so you will need to be aware of the limitation of certain drain types for your processing plant’s needs.

Making sure that you are aware of the kinds of drains that will be needed for high volumes of liquids as well as the right kinds of drains to use in high traffic areas can be essential to planning an effective and safe drainage system. It is always a good rule of thumb to be aware of the exact amount of liquid waste that your plant produces in a day as well. The amount of solids and debris that will need to be collected and disposed of each day is an important factor.

4 Things to Think About When Selecting and Designing Your Food Processing Plant Drainage

1. Ease of Cleaning

Gates and angles in the drains, as well as drains that are far from the central part of the main workspaces, can be locations that mud and sediment can collect. This can lead to issues with clogged drains and breeding grounds for bad smells and dangerous bacterial growth.

You will need to plan your drainage system to be sure that these areas can be cleaned easily and to avoid areas that will hold onto and trap debris. There are many kinds of solutions for this sort of troubleshooting and you will need to make sure that you plan proper access for cleaning into these areas of your workspaces.

2. Regulations and Code Guidelines Surrounding Food Processing Drainage

This is an essential consideration when you are planning a drainage system. Your facility will need to meet code and all regulations for your state or county to be able to operate each day. A good drainage system is not just a matter of convenience for your daily work processes. It is also part of your legal requirements to meet state and county or even national codes.

No matter which state your business is located in, you will need to be familiar with the sanitation and safe operations codes and regulations that are expected of your business. Many of these codes and regulations will affect what kind of drainage system you need to install and the requirements of your daily operation for sanitation and safety can be greatly affected by an incorrectly installed drainage system.

Food processing locations are required to undergo thorough cleaning daily and this usually includes scrubbing drain surfaces and gates. This is why it is so important to think about the kind of drainage system you are going to install well in advance of the actual installation project. There are many ways to make your drainage system easier to access, operate, and sanitize and you will want to pick the right drain styles and types to optimize this process.

3. Be Able to Withstand High Temperatures and Chemical Waste

Food processing can involve chemical waste as well as very high-temperature fluids. These fluids will need to be drained off and properly prepared for entry into the sewage system. This means that your drains in the actual preparation floor will need to be made to withstand these challenges.

Stainless steel is the preferred choice for these working conditions, but there are other styles of drain that can be used as well. Corrosion can undermine any drain system, so you will need to be sure that your selected drainage style will hold up to the challenges of your business’s daily activities.

Another consideration that will need to be made related to chemical waste and high-temperature runoff, is a storage tank that can hold onto these fluids until they have been properly prepared for entry into the sewage system. Not all kinds of chemicals can be drained as sewage. The kind of decontamination processes that your business type is required to undergo each day will dictate what kinds of hold tanks and other solutions you will need to build into your drainage system.

4. Proper Drainage for a Safe Food Processing Plant

Your drains need to work properly but they also need to be safe for your staff and visitors to your plant. You might have the best drains in the world on your processing room floor, but if the drain covers are not sealed properly or the floor is not correctly leveled, you could be creating great risk for slips and falls.

Incorrectly finished drains can also lead to standing water, which is dangerous from a slip and fall perspective as well as a sanitation perspective. You will need to make sure that every part of your drainage system is safe for the activities that are going on around it all day. Uneven floors or poorly fitted gratings and slot drains can do more harm than good to your business’s safety.

What Kinds of Drains Should You Use in a Food Processing Plant?

Trench drains have been around since people began farming. This is the most basic style of drain, and it is the building block that all other drain types are built off of. This is going to be the primary kind of drain that you will use in any kind of food processing plant, but there are important upgrades and accessories that will need to be put in place as well.

You cannot operate your business with open trenches in the floors and you will need to be sure that you utilize the right kinds of connection points between types of drains and your storage tanks or water holding locations.

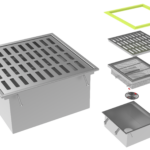

Point Drains

This kind of drain collects water from a single point to drain into your trench drains. These drains will be at the center of a sloped floor. This is the right kind of slot drain to install at a point where runoff can come from many locations.

These drains can be hard to install correctly and even harder to retrofit into a floor that was not properly built for the use of this kind of drain. You will want to be sure that you work with the right experts to install these drains so that they do not become a source of ponding or a possible slip and fall hazard.

These drains will not be used in high traffic areas as they affect the surface of the floor too much to be suitable in areas where workers must walk around all day or where machinery needs to be operated. You will want to use these drains in smaller areas where spills are common and good drainage is harder to secure.

Trench Drains with Slotted Grates

These are the mainstay of many food processing drainage systems. You will install the trenches at any depth that is sufficient to handle the level of runoff that your business experiences in a day. You can build these trenches deeper as needed to handle large volumes of liquids.

These drains will be protected by slotted drain covers that can be removed for easy cleaning of the trench drain that lies beneath. Slot covers can be made in many different styles and designs to handle specific kinds of runoff. If you are planning to prevent debris from entering the drain, you will want to pick a smaller size slot drain cover.

Most of these drains are going to need to be made of stainless steel for this kind of environment and you will find that your slot covers will hold up for much longer if they are also made of stainless steel. DuraTrench offers many products that are made specifically to hold up to chemical runoff and high-temperature runoff.

If you need to make sure that your drains will hold up to a lot of daily abuse, you should shop through the industrial use drains that DuraTrench makes for this kind of need. You might be able to use a different style of drain in some areas of your business, but our industrial-specific drains are usually the right choice for your high traffic areas where preparation and other tasks are done all day.

Slot Drains

These cleverly designed drains offer the perfect blend of benefits when they can be applied to a portion of your drainage system. They are a smaller drain but they are much lower-profile and they are much less likely to cause tripping hazards or risks of slips and falls.

Slot drains are also very durable as they are made of a single solid piece of material and do not have multiple moving pieces that have to remain in place during daily activities. The lack of a grate on top of these drains makes them the perfect fit for areas that see a lot of foot or machine traffic during business hours.

These drains are usually quite cost-effective and are easy to install. They are not going to be able to handle the volume of liquids that a traditional trench drain can handle, but they are capable of dealing with runoff in foot traffic locations or warehouse floors.

An added benefit to this kind of drain is that it can be cleaned using a single brush which pushes debris through the drain and out of this part of the drainage system. This is not a feature of open drain styles, and slot drains can offer ease of cleaning that is not a possibility when you are working with larger drain types.

In some kinds of food processing, such as poultry plants, these kinds of drains are recommended for any area that might be dealing with contaminants. It is much easier to keep sludge out of these kinds of drains and clean drains will not grow bacteria from animal product processing. Using a trench style of drain in poultry or other meat processing locations can lead to issues with bacterial growth after even a single day of operation.

Dura Trench offers many sizes and designs of slot drains that can be used to fill this need in your overall food processing plant drainage system. You will find exactly the right slot drain for your needs and our proprietary materials are hardy enough to stand up to the tests of time and daily use.

Additional Accessories to Your Food Processing Plant’s Drainage System

For many manufacturing locations, catch basins and sumps are needed to handle the debris and chemical wastes that are being produced during daily working hours. You will need to assess the volume of wastewater and related debris that is generated during a normal business day to be sure about which size catch basins you will need to install.

You can order these batch basins and sump arrangements in any material and you can pick from a variety of styles and sizes. The ultimate determination of your needs related to this kind of water and debris collection depends on the location of the catch basin in your overall drainage system and the kind of access that you will need to have to it when solids need to be removed.

Make sure that whatever kind of catch basin you select will be able to handle chemical and high-temperature runoff and that it is located in the right spot in your drainage system to collect all of the debris and other detritus that you do not want to wash out into the sewage system each day.

These locations can be rife with issues if the floor is not properly prepared before the installation of the catch basin, so you might need to work with a skilled technician to make sure that the slope of your floor is appropriate for the catch basin. Additionally, if this catch basin has to be located in a high-traffic area, you will want to pick the right kind of slot cover or grate to prevent slips and falls at this location.

Add Catch Basins at Outlets as Needed

There are some kinds of food processing that necessitate that outlets have their own catch basins. Manufacturing locations for meat products and sodas have these kinds of regulations in place to prevent contaminated wastewater from being delivered to local run-off locations or to the sewage system. These kinds of catch basins are required by law to protect the environment as well as the health of people who live in the area of your business.

These kinds of catch basins can be designed to hold contaminants and debris that should not be released into the local water supply or sewage systems. These basins are typically cleaned daily as dictated by the rules and regulations of your unique food processing niche. Forgetting to install catch basins at outlets into the sewage system or local waterways can cause major environmental issues related to your business.

Always make sure that you do not install the wrong kind of large catch basins for this type of runoff. You do not want to contaminate local water sources and you will not enjoy paying the fines related to the clean up of a toxic mess.

Make Sure That Your Drainage Solution Can be Thoroughly Cleaned

The general guidelines for cleaning in food processing plants are centered just as much around the prevention of contamination of other surfaces as they are with defeating the growth of bacteria in the drainage system. Every step of the cleaning process should be possible if you have installed the right drainage system for your needs.

If you are not sure that all of the parts of your selected drainage system will work for your stated regulations related to cleaning. It is simple to make sure that each of your installed drainage products will meet regulations and standards for safe operation if you consider the daily processes that must be done to clean and care for them.

- Make sure that drain covers, strainers, and slot covers can be removed and sanitized and cleaned each day.

- Make sure that trench drains can have any debris removed from them with ease.

- Make sure that there are no bends or angles in the proposed drains that will collect standing water or debris that could lead to contamination and bacterial growth.

- Be sure that standing water does not collect near drains and drain covers

- Consider if water will run down into the drains smoothly or if it will need to be pushed toward the drains manually

If any part of your proposed drainage system cannot be cleaned readily, you will need to rethink that part of your new drainage system. You should never settle for a drainage solution that does not allow for your food processing location to be cleaned and sanitized easily each day.

Between the risks of accident and injury and the chance of breeding bacteria and contaminants, you need to be sure that your drainage solution will not cause more harm than good to your business.

Make Sure to Get Expert Assistance With Your Food Processing Plant Drainage System

If you are not sure about the right way to design your drainage system for your food processing plant, it might be wise to work with an expert technician who can help you to design the right drainage solution for your needs. Food processing plants are governed by strict rules and regulations and you will need to be able to prove that you are following all of these guidelines to be able to stay open for business.

Upgrading Your Food Processing Plant’s Drainage System is a Great Investment

If you are ready to upgrade your food processing drainage system to a better and more environmentally friendly one, we at Dura Trench can help you out! There is no job that is too big or too small for our team of experts, and we can help you design the perfect drainage system for your unique needs. We have lots of experience working with food processing drainage systems and we know how to set you up with perfect products to handle your needs.

Contact us today and we will work with you to develop the perfect drainage system for your needs.