Pharmaceutical production facilities have to adhere to specific standards to be able to operate safely. You need to be sure that you are prepared to handle the compliance process in order to stay open for business if you are going to operate a facility of this kind. Production facilities need to be sure that they are handling products and processes properly to protect the public.

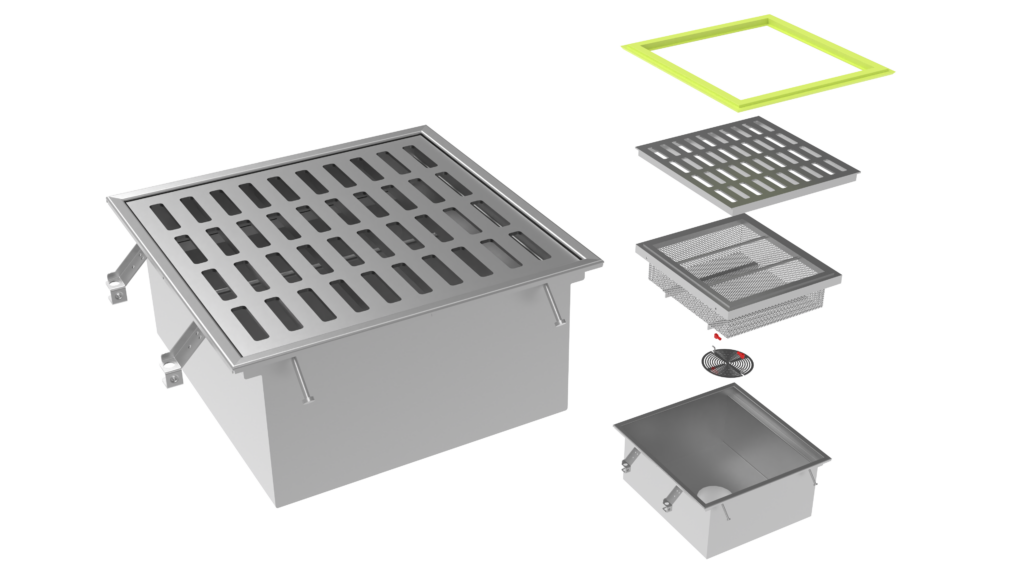

One of the key aspects of compliance in this industry is the right floor drains for pharmaceutical production facilities. You need to ensure that there is no standing water on the floor during production hours and that you can clean up properly in between tasks and at the end of the day. Drainage is one of the main components of a healthy and safe facility.

Elements for Compliance With Federal Regulations for Pharmaceutical Production Locations

1. Proper Drainage

As with all production entities around the world, water and liquids are often used to make products. In the case of pharmaceutical facilities where medications are made, the liquids that are used for the production process can easily contaminate other batches of products or might be harmful if staff are exposed to them for long periods of time. This is why drainage is so important for safe and compliant operations in these locations.

You will likely have specific requirements that you need to adhere to for each kind of drug or process that you are engaged in when you are creating medications. You need to be sure that the drainage that you install helps you to keep to these standards with ease. Not all drainage is the same, and some kinds of floor drains will not meet the requirements for cleanliness and safety in your facility.

Drainage needs to be correctly set up throughout your entire facility, so you might need to work with a drainage expert to be sure that you are getting the right drainage setup at your production location for safety and federal compliance.

2. Maintaining Cleanliness

Depending on the kinds of products you are making, there will be different, unique cleaning processes that need to be handled each day in your facility. You need to observe these cleanliness requirements perfectly when you open for business, or your company could be shut down or face expensive fines.

Maintaining a clean working area is critical to prevent slips and falls and also to ensure that your products are not being contaminated. You might need to adhere to specific drainage cleaning processes, or you could need to fully flush the entire area and sanitize it after each batch of product is made. Whatever the requirements are for your specific kind of operations, you have to stick to these requirements to avoid fines and shutdowns.

3. Maintain Equipment

You need to have a zero tolerance rule for machinery that is not working correctly at your facility. The margin of error for the pharmaceutical industry is very slim. This is to protect public health. Your business needs to maintain equipment correctly and ensure that machinery that is not working correctly is pulled from circulation until it is fixed.

There are various ways to check the health of your machinery and assembly lines without having to do a visual inspection each day. Investing in smart technology solutions can help your machinery report that it is having issues well before a potential consumer health risk occurs.

4. Raw Material and Product Controls

There are various factors that are important to monitor when you are making medications and other drugs. You need to be sure that the raw ingredients for your products are at the correct strength and are properly stored so that they do not go bad. Some of these ingredients might be risky to handle in their native state, which will require specific fail-safes to be in place to protect the workers at your business.

Your products will also need to be carefully tested before being sold, which requires another set of quality control processes. You will not be allowed to miss any of these steps in the process of creating medications, and your teams of workers need to be aware of the correct ways to protect consumer health and their own safety as they are handling raw materials and products.

Be sure that there is training on these processes and that staff members are always following the important safety practices that are critical to your industry.

5. Internal Audits

Auditing for safety and compliance needs to be carried out at every level of your business operations throughout each month. You need to be checking on the quality of the products that you are making, and you need to ensure that safety practices are being followed each day. You should also make sure that the staff are taking proper safety precautions and steps.

All of these audits can reveal trends over time that will allow you to ensure that your facility is not the origin point for major problems that could have been avoided. You should never wait until a significant problem happens to start checking up on quality controls.

Operating in the Pharmaceutical Space Requires Diligence and Compliance

Safe operation of a facility that creates medication and pharmaceutical products is essential. You can face fines and shutdowns if you are not adhering to federal standards. Be sure that your business is not plagued by problems that could have been avoided by ensuring that safety and federal requirements are a key area of focus for your staff and your business as a whole.

Proper cleaning and sanitation are essential aspects of federal regulations for pharmaceutical production locations. You will need the right floor drains in place in your facility so that your teams of workers can clean and prep workspaces throughout the workday. Be sure as well that safety guidelines and proper storage protocols are in use. All of these factors need to be present for your business to operate smoothly and safely each day.